The Nyirambagasa valley in Kacyiru is well-known for one thing; its abundance of a sticky clay soil variety that is the ultimate gem for every clay artisan.

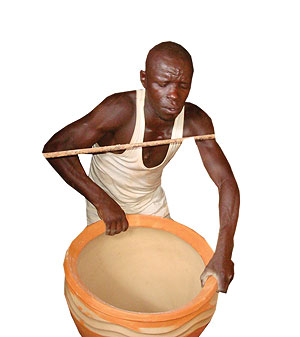

The Nyirambagasa valley in Kacyiru is well-known for one thing; its abundance of a sticky clay soil variety that is the ultimate gem for every clay artisan. For this reason, the area boasts a long history in the pottery business. A boy or girl was born, saw his or her parents and elder siblings make clay works for a living, and soon, he/she was an apprentice, gaining practical skills in the trade. Nearly a generation of clay artisans cut their pottery teeth this way. Soon, there were so many potters in Kacyiru, all equipped with a similar art and all chasing the few available buyers then. Desperate for alternative sources of income, some of them started to venture into other income-generating activities like farming. The Kigali Ceramic Filter Factory (KCF) in Kacyiru had such roots. In 2008, a group of disgruntled artisans, numbering 48 in total decided to join hands in the form of a loose famers’ cooperative. They had no memorandum of understanding, written contracts or any other such binding documents expected of a bona-fide coop. They didn’t even have land on which to locate their coop. All they had was the idea. So they went about their work, tilling their individual plots of land and planting maize, beans, cabbage, potatoes and onions. A few also carried on with their pottery works, taking advantage of the abundance of rich clay soils freely available in the nearby Nyirambaragasa swamp.But the problem of lack of a permanent workshop for the potters kept haunting the group. A plan was mooted and the group sought audience with government through Akareere ka Gasabo. They wanted land.Their request could not have had a better timing, for no sooner had the group made their plea, than the government advanced it 5 acres of land for use at their discretion. The site is where the Kigali Ceramic Filter Factory (KCF) proudly stands today. The factory makes a wide range of clay products like outdoor flower vases, trinkets, charcoal ovens and decorative pieces. When you visit the site, you are immediately greeted by the sight of men and women drenched in clay, trying to forge an object out of a mound of clay. By far, flower vases and animal statues take the biggest part of their production time as they are the most sought-after by clients. c Inside the main building, huge pots and elegant flower vases are stashed away neatly in endless rows. Behind this building is a huge wood oven through which all clay works must go for the baking process. This is necessary not only for reinforcing its strength, but also gives it a finer texture. Standing about 2 metres from the mouth of this oven, I could barely contain the heat permeating from it, and had to step back a little. Which made me wonder how the two young men clad only in vests managed to climb into the oven and haul out huge pots from it. After the pots are baked, they indeed remind one of baking. They acquire a fresh and sweet scent that eases the industrial atmosphere in the factory. With the success of the pottery scheme, the coop. has been spreading its wings further into alternative money-generating activities. Last year, the group applied for and received 29 Friesian cows through the Gira inka presidential initiative, in which high breed cows are given out to the poor. Today, the group reaps just as much money from the sale of milk. Recently, the coop. also ventured into lawn mowing, and installing coal ovens in private homes. One of the most cherished items at KCF is the water filter. It is made of the rare white clay (ingwa) from Mbaragasa swamp. This clay vessel is placed into a bigger plastic vessel, and water poured into it. The clay vessel is made with small pores at the bottom through which the water filters to the outer vessel. This purification procedure is apparently so effective, it can purify even run-off rain water and make it fit for human consumption. So effective it is, it caught the attention of the UN agency, Unicef.Recently, Unicef decided to fund the water filter project, funding the production the white plastic buckets used in the process. Inside one of the rooms, I was shown thousands upon thousands of these white buckets, stashed high up to the roof. According to Asuman Rwamirera, a founder member and assistant vet at KCF, the water filters have a wide penetration in remote villages where access to safe water is hard. "Some of our orders come from as far as Burundi,” he notes. Emmanuel Dushime Imana, who I found mending a broken flower vase by melting plastic on it confessed to have inherited the craft from his forefathers who, like him, lived in this area. He is all praises for the coop., saying it has kept him from stealing to put food on the table. Besides, he says, "it makes me meet people I would never have met.” Things seem to be looking up for the coop. But one problem still bedevils it though; that of a car. Says Imana: "We need a purpose-built car to carry clients’ orders to their homes because our products are fragile. Most clients buy things but they break along the way because of poor handling.”