Six students from the University of Rwanda’s College of Science and Technology (former KIST) have designed an automated solar-powered eggs incubator aimed at lowering the cost of poultry incubation in the country.

Six students from the University of Rwanda’s College of Science and Technology (former KIST) have designed an automated solar-powered eggs incubator aimed at lowering the cost of poultry incubation in the country.

A students’ initiative under an association dubbed REtronics designed a solar and grid-run portable poultry eggs Incubator, which they believe will facilitate poultry production in the country.

Speaking to The New Times in Kigali yesterday, Hilary Muramira, a member of the REtronics, said: "The incubator will be sold at Rwf150,000 to make it accessible for all local poultry farmers.

Rwanda has four incubation centres which include; Rubirizi, Gahanga, RwandaGic and Rulindo, and most of them import eggs and chicks from Europe and South Africa, which makes it expensive.

"Farmers are going to have an alternative,” said Muramira during an event organised to celebrate the World Telecommunication and Information Society Day at Lemigo Hotel in Kigali last Saturday.

The Day involved innovation exhibitions where various young innovators showcased various ICT-related gadgets.

"We want to be part of the solution,” Muramira said, adding that as students of technology, it is impractical to leave school and seek employment.

All products exhibited focused on encouraging young Rwandans to come up with home-grown solutions to national development challenges.

How the project started

During a meeting held at Klab, a local technology entrepreneurship breeding centre, the six electronic engineering finalists from the College of Science and Technology, brainstormed on how they could come up with a project that would fit the local market.

"Our aim was to contribute to national development in line with Vision 2020. The egg incubator turned out to be the best idea,” Muramira said.

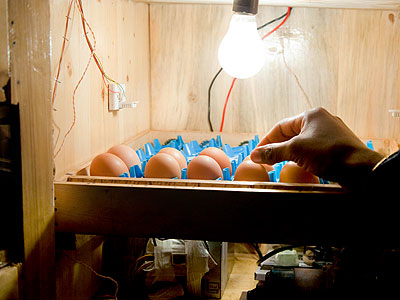

The egg incubation system consists of a power supply unit, an energy storage unit and the egg incubation chamber.

The incubator is capable of handling up to 42 eggs per batch of incubation. However, the designers say the capacity varies depending on the customer’s preferred size.